Maximize Your Wind Turbine’s Uptime.

Inspect 4+ turbines daily. Outperform rope access. Secure audit-ready proof.

The Expert Platform for Wind Farm Teams

Common industry challenges:

Weeks lost processing disconnected data shipped overseas for interpretation. Vendors without structured implementation support leave operational risk with your team.

The Operational Fallout:

Your team wastes time wrestling with fragmented data while critical findings are missed or delayed. Implementation becomes improvisation. Despite your best efforts, you are left managing operational disruption that threatens your professional reputation.

Autonomous Inspections with Predictable Results

TOPseven’s autonomous wind turbine inspection platform combines visual and mechanical testing with German engineering. We deliver accepted reports without the need for retakes or rework.

High-precision Imaging

Continuous capture eliminates waypoint stops.

German-engineered precision imaging with established accuracy standards.

Expert manual camera control for professional judgment situations.

Professional exposure adjustment maintaining optimal detection conditions.

Contact-less LPS testing

Contactless LPS testing integrated in flight mission gaps.

Complete rotor blade health analysis in single comprehensive mission.

Contactless mechanical data reducing safety risks and operational costs.

Expert Control Architecture

Manual override capabilities for complex inspection scenarios.

Professional workflow integration with existing quality standards.

Expert parameter control maintaining professional inspection autonomy.

01 Plan

Our system calibrates the mission to the actual asset geometry before takeoff, automatically detecting blade positions and computing the precise flight path your team will execute.

02 Execute

Your operator initiates the mission. The system executes the standardized route, capturing continuous visual and LPS data, and verifies complete coverage before landing.

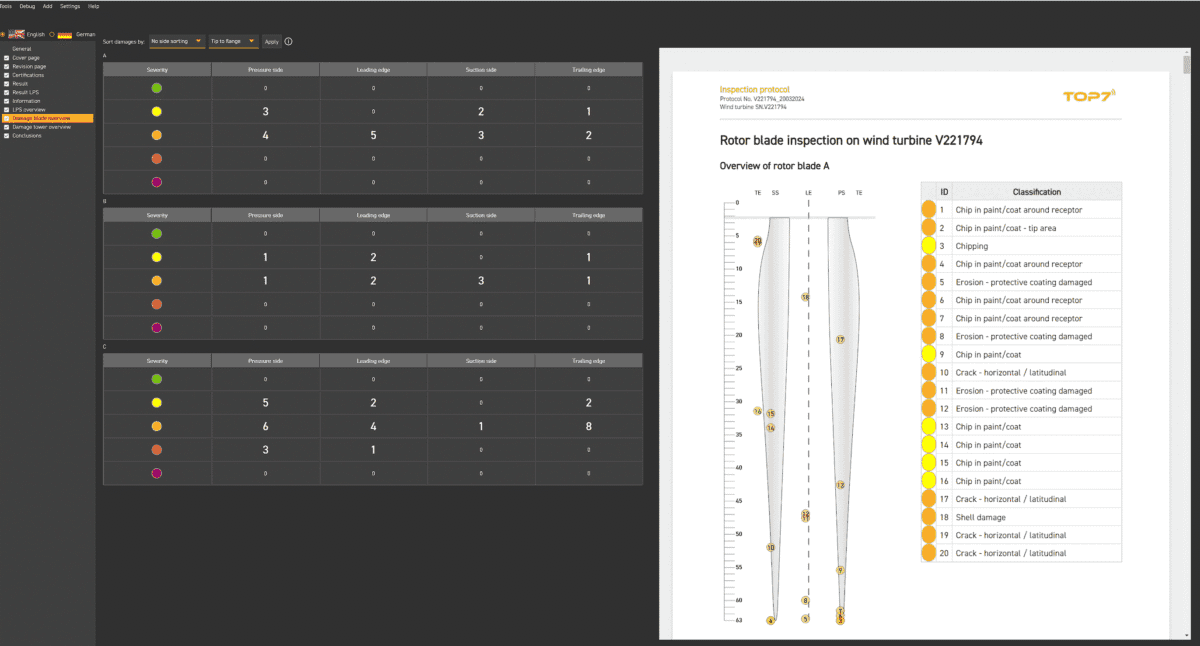

03 Analyze

Your experts review imagery mapped directly onto the asset structure, classify damage using standardized severity scales and generate audit-ready PDF reports directly from the platform.

04 Govern

Your organization manages teams, enforces permissions, and archives every mission with full traceability from capture to signature for any audit request.

From Risky Climbs to Reliable Throughput.

Expert Reliability You Can Trust.

Our blade inspection experts work directly with your team through systematic implementation and provide ongoing technical support. We understand implementation complexity because we are wind industry professionals first, committed to your long-term operational success and reputation protection.

Frequently Asked Questions

Answers to common questions about getting started and using TOPseven day to day.